2025 New Regulation Update: What Hidden Requirements Are There for UN38.3 Test Reports in Lithium Battery Maritime Shipping?

**

In today’s globalized trade landscape, lithium batteries, as the core of the new energy industry, have seen their application scope expand continuously—from consumer electronics to electric vehicles—with demand growing explosively. This trend has led to a surge in maritime shipping demand for lithium batteries. However, due to the potential safety risks of lithium batteries, such as overheating, fire, and even explosion, their transportation process is subject to strict regulation. Among these regulations, the UN38.3 test report serves as a key access document for lithium battery maritime shipping. With a series of new regulations in 2025, there are numerous easily overlooked hidden requirements in these reports.

Current Status of Lithium Battery Maritime Shipping and the Importance of UN38.3 Test Reports

With the vigorous development of the new energy vehicle industry and the popularization of portable electronic devices, the output and export volume of lithium batteries have increased year by year. According to statistics from the International Energy Agency (IEA), the global lithium battery shipment volume reached [X] GWh in 2024, a year-on-year increase of [X]%, with a large portion transported across borders by sea. However, the chemical substances contained in lithium batteries may pose hazards under specific conditions. To ensure maritime transportation safety, the International Maritime Organization (IMO) clearly stipulates in the International Maritime Dangerous Goods Code (IMDG Code) that lithium batteries must pass the UN38.3 test and provide corresponding reports for maritime shipping. The UN38.3 test aims to simulate extreme environments that lithium batteries may encounter during transportation, such as high temperature, low temperature, vibration, and impact, to verify their safety. A qualified UN38.3 test report is the foundation for legal and safe maritime shipping of lithium batteries and a key focus of inspections by ports and maritime authorities.

Analysis of Hidden Requirements in UN38.3 Test Reports Under 2025 New Regulations

1. Refinement and In-depth Requirements for Test Items

- Accuracy Requirements for High-Temperature External Short-Circuit Test: In the high-temperature external short-circuit test, the 2025 new regulations have raised higher requirements for the accuracy control of test temperature. Previously, a certain temperature deviation might have been allowed, but the new regulations require the test to be conducted in an environment of (55±2)℃, significantly narrowing the temperature deviation range. This means that the temperature control system of test equipment must have higher precision to ensure the stability of the test environment. For example, a well-known battery manufacturer previously conducted tests with temperature controlled around 55℃ but with fluctuations of ±5℃—such fluctuations will render the test results unrecognized under the new regulations. In addition, the recording of short-circuit duration has become more stringent, requiring second-level precision to record the entire process from the occurrence of the short circuit to the battery reaching a thermally stable state, thereby enabling a more accurate assessment of battery performance under high-temperature short-circuit conditions.

- Current Stability in Forced Discharge Test: The forced discharge test is designed to verify the safety of batteries under abnormal discharge conditions. The new regulations stipulate that the current during discharge must be maintained within ±5% of the specified value, whereas some enterprises previously allowed fluctuations of ±10%. For instance, for a lithium battery with a rated discharge current of 5A, the current during testing must be stabilized between 4.75A and 5.25A. This poses a significant challenge to the current output stability of test equipment. Unstable current may cause abnormal reactions of the battery during testing, affecting the accuracy of test results and consequently leading to the UN38.3 test report being rejected.

2. Completeness and Standardization of Report Content

- New Requirement for Lithium Battery Material Composition Description: The 2025 new regulations require detailed descriptions of lithium battery material compositions in UN38.3 test reports, including positive and negative electrode materials and electrolyte components. Different material compositions present varying risk levels during transportation. For example, lithium batteries with lithium cobalt oxide positive electrodes differ from those with lithium iron phosphate positive electrodes in thermal stability and safety. The report must clearly indicate the chemical names and purities of positive and negative electrode materials, as well as the proportions of various solutes and solvents in the electrolyte. A battery manufacturer previously only mentioned “lithium compounds” as the positive electrode in its report without detailed specifications—such a report will be deemed incomplete under the new regulations.

- Detailed Recording of Test Equipment Traceability Information: The report must include traceability information of the equipment used for testing, such as the equipment manufacturer, model, calibration certificate number, and calibration validity period. This is to ensure the accuracy and reliability of the test equipment. For example, a multimeter used to measure battery voltage must have its manufacturer (Fluke), model (17B+), calibration certificate number ([specific number]), and calibration validity period ([specific date]) specified in the report. Using this information, inspectors can trace the calibration status of the test equipment and judge the credibility of the test data. Missing such information in the report may lead to questioning or rejection of the report.

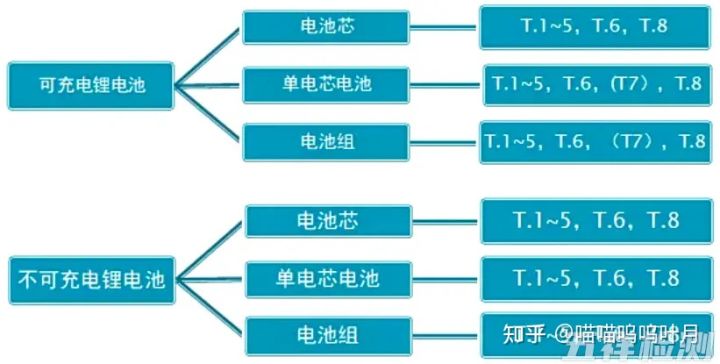

3. Manufacturer Declaration and Traceability Requirements

- Independent Declarations for Single Batteries and Battery Packs: The new regulations stipulate that manufacturers must provide separate declarations for single batteries and battery packs. The declaration content includes information such as battery model, specification, production batch, and compliant standards. For example, a mobile phone lithium battery produced by a brand requires one declaration as a single battery; when multiple such batteries are assembled into a battery pack for energy storage equipment, the battery pack also requires a separate declaration. The declaration must be stamped with the manufacturer’s official seal and signed by the relevant responsible person. If a manufacturer only provides a general declaration without distinguishing between single batteries and battery packs, it will fail to meet the new regulatory requirements.

- Consistency of Production Batch Traceability Information: UN38.3 test reports must reflect the traceability information of lithium battery production batches, and this information must be consistent. Records from raw material procurement, batch marking during production, to batch marking on final product packaging must correspond to each other. For example, during the production of a batch of lithium batteries, if raw materials are purchased from different suppliers, detailed records must be kept of the purchase time, supplier name, and raw material batch number for each batch. During production, the batch marking at each production step must correspond to the raw material batch, and the batch number on the final product packaging must also be consistent with the batch information during production. In this way, if problems arise during transportation, the root cause can be quickly identified through this traceability information, ensuring transportation safety. Discontinuous or unclear traceability information may affect the validity of the report.

4. Requirements for Correlation Between Transportation Conditions and Reports

- Consistency Between Transportation Packaging and Test Conditions: The transportation packaging of lithium batteries must be consistent with the packaging conditions used during the UN38.3 test. The report must detail the packaging form and materials used for the battery during testing. For example, if the lithium battery used a flame-retardant plastic casing of a specific thickness and was fixed with cushioning materials during testing, the packaging during transportation must be identical. If the transportation packaging is altered—such as changing the packaging material or simplifying the packaging structure—the battery may be deemed to be transported in violation of regulations even if it has passed the UN38.3 test. Different packaging conditions may affect the safety of the battery during transportation, so ensuring packaging consistency is an important requirement under the new regulations.

- Clear Marking of Transportation Restrictions in Reports: UN38.3 test reports must clearly mark the transportation restrictions for lithium batteries, such as maximum stacking layers, transportation temperature range, and humidity limits. Taking the transportation temperature range as an example, some lithium batteries are prone to thermal runaway in high-temperature environments, so the report may specify that the transportation temperature must be controlled between -20℃ and 40℃. Shipping companies must strictly comply with these restrictions during transportation, and ports and maritime authorities will also conduct inspections based on the markings in the report. Failure to clearly mark these transportation restrictions in the report or violating the marked conditions during actual transportation may result in cargo rejection or penalties.

Case Studies: Maritime Shipping Disruptions Caused by Non-Compliant UN38.3 Test Reports Under New Regulations

1. Case of a Well-Known Electronics Enterprise

A well-known electronics enterprise exported a batch of laptop batteries and submitted a UN38.3 test report during customs declaration for maritime shipping. However, port inspectors found that the temperature records in the high-temperature external short-circuit test in the report showed significant fluctuations, exceeding the ±2℃ range required by the new regulations. Although the enterprise explained that no safety accidents caused by temperature issues had occurred during actual use, the cargo was temporarily detained due to the non-compliant test report. The enterprise had to rearrange the test, incurring substantial time and costs. Not only was the delivery schedule delayed, but the enterprise also faced customer claims, which negatively impacted its reputation.

2. Case of a Small Battery Manufacturer

A small battery manufacturer exported lithium batteries to overseas customers, but its submitted UN38.3 test report failed to include the lithium battery material composition description required by the new regulations. Port customs deemed the report information incomplete and unable to accurately assess the transportation risks of the batteries, thus refusing to release the cargo. The manufacturer had not previously paid attention to the changes in the new regulations, resulting in the cargo being held in the port warehouse. Due to the long time required to supplement materials and apply for retesting, the customer canceled the order, causing the enterprise to suffer significant economic losses.

Strategies and Recommendations for Responding to the New Regulations

1. Upgrading Internal Quality Control Systems

- Establishing Strict Test Procedures and Standards: Enterprises should re-examine and improve their internal UN38.3 test procedures in accordance with the 2025 new regulations. Develop detailed test operation manuals that specify the specific requirements, operation steps, and data recording standards for each test item. For example, for vibration tests, specify the specific ranges of vibration frequency, amplitude, and test duration, as well as how to monitor and record battery status changes during the test. At the same time, establish an internal audit mechanism to regularly review the test procedures and ensure the standardization and accuracy of test operations.

- Strengthening Employee Training and Skill Enhancement: Organize employees to participate in training courses on the 2025 UN38.3 new regulations and invite industry experts to give explanations. The training content should not only cover the specific requirements of the new regulations but also include the correct use of test equipment and the analysis and processing of test data. Through training, improve employees’ understanding and implementation capabilities of the new regulations to ensure strict compliance with the new requirements in practical work. For example, provide targeted training to technical personnel responsible for testing to help them master the refined accuracy requirements for test items and avoid test report non-compliance due to human operation errors.

2. Cooperating with Professional Testing Institutions

- Selecting Compliant and Professional Testing Institutions: When choosing UN38.3 testing institutions, enterprises should strictly examine their qualifications and professionalism. Ensure that the testing institution has relevant certification qualifications, such as accreditation by the China National Accreditation Service for Conformity Assessment (CNAS), and has rich experience in lithium battery testing. Evaluation can be conducted by checking the institution’s historical test cases and customer reviews. For example, a testing institution with years of experience in lithium battery UN38.3 testing has successfully provided compliant test reports for many well-known enterprises, and its professionalism and reliability are recognized by the industry.

- Maintaining Close Communication with Testing Institutions: During the testing process, enterprises should maintain close communication with testing institutions to timely understand the test progress and potential issues. Discuss solutions to the hidden requirements in the new regulations with testing institutions. For example, when questions arise about the standardization of report content, enterprises can communicate with testing institutions to clarify the specific filling methods for newly added content such as lithium battery material composition descriptions, ensuring that the test report meets the new regulatory requirements. At the same time, enterprises can request testing institutions to provide detailed test process records and original data for their own review and archiving.

3. Monitoring Regulatory Dynamics and Engaging in Industry Exchanges

- Establishing a Regulatory Tracking Mechanism: Enterprises should assign dedicated personnel to track changes in regulations related to UN38.3 testing. Monitor the latest regulations and notices issued by the IMO, national maritime authorities, and industry associations to obtain timely information. For example, regularly browse the regulation update section on the IMO official website and subscribe to regulation push services from relevant industry information platforms. When new regulations are released, promptly organize internal discussions to analyze their impact on business operations and formulate corresponding response measures.

- Actively Participating in Industry Exchange Activities: By participating in industry seminars, forums, and other exchange activities, enterprises can share experiences with peers and learn about other enterprises’ approaches to coping with the new regulations. For example, at a lithium battery transportation safety seminar, enterprise representatives exchanged experiences in addressing the hidden requirements of the UN38.3 test report new regulations with other participating enterprises and learned effective solutions, such as optimizing the calibration process of test equipment and improving the writing standards of report content. Industry exchanges help enterprises broaden their perspectives and better adapt to regulatory changes.

Under the 2025 new regulations, the UN38.3 test reports for lithium battery maritime shipping contain numerous detailed and strict hidden requirements. From the high-precision control of test items to the comprehensive standardization of report content and the close correlation with transportation conditions, every link poses higher challenges to lithium battery manufacturers, shipping companies, and relevant institutions. Only by deeply understanding these hidden requirements and proactively adopting response strategies can enterprises avoid disruptions in lithium battery maritime shipping, ensure the smooth transportation of goods, and simultaneously safeguard the safety and stability of maritime transportation.